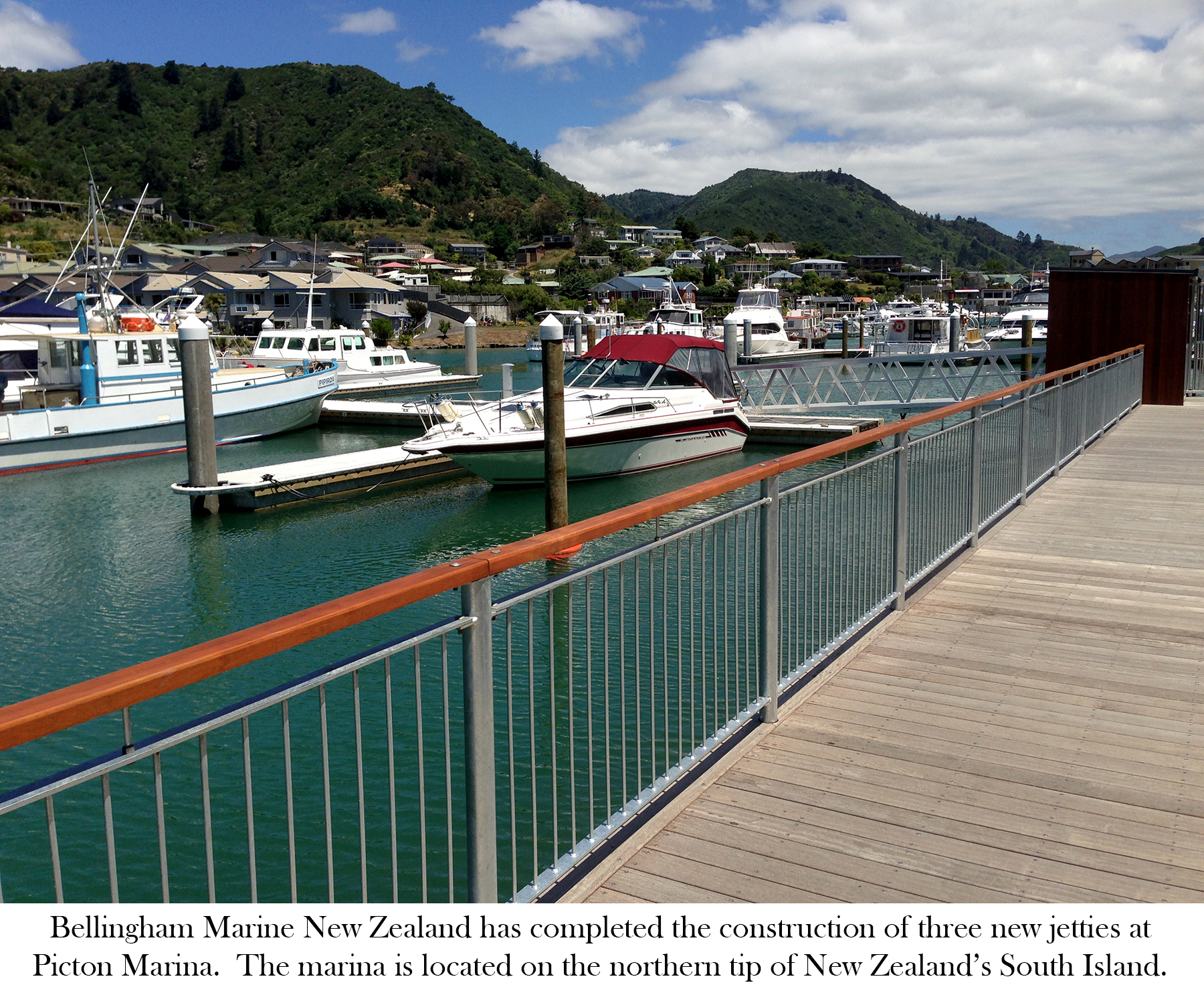

Located on the northern tip of New Zealand's South Island, the beautiful Picton Marina now boasts three new jetties, recently completed by Bellingham Marine New Zealand. The marina can accommodate a total number of 232 yachts measuring up to 35m in LOA. ... read full story

Latest News

Popular News this Week

Popular News this Month

Featured Locations

Bellingham Marine Luxury Yacht Charter & Superyacht News

Marine13 Program Update

Written by

All about setting a new course for the marine industry, the highly anticipated Marine13 International Conference and Exhibition will take place in Sydney, from April 28 to 30, hosting such important speakers as Everett Babbitt, President & CEO of Bellingham Marine. ... read full story

Bruce Birtwistle – New General Manager of Bellingham Marine New Zealand

Written by

Bruce Birtwistle has been appointed as new General Manager of Bellingham Marine New Zealand. He will manage the company's New Zealand as well as South Pacific operations. ... read full story

Bellingham Marine’s new terminal for Flagship Cruises completed

Written by

Designed and constructed by the world renowned marina design-build construction company, Bellingham Marine, the new terminal for Flagship Cruises in California's San Diego has been recently completed. ... read full story

First China Marina Conference attended by Bellingham Marine’s John Spragg

Written by

Taken place at the recently completed Nansha Marina from October 10th to 11th, the inaugural China Marina Conference was attended by Bellingham Marine General Manager of Australasia, John Spragg. ... read full story

A new member to Board of Marina Industry Association of Australia

Written by

During the August Marina Industries Association (MIA) Board meeting, Kenny Kang (Seuk-Ju, Kang), Chief Executive Officer of CKIPM Marine Group Co Ltd became the new member of the Board of Directors. He is the first MIA director not coming from Australia. ... read full story

Bellingham Marine appoints David Lamont as New Operations Manager

Written by

As part of its New Zealand division, David Lamont will work as Operations Manager of Bellingham Marine, the respected superyacht marina builder, well known all over the world. ... read full story

CKIPM and Bellingham Marine team up to give presentation at the 2012 Jeju Forum for Peace & Prosperity

Written by

Running from May 31 to June 2, the world's leading marina design-build construction company, Bellingham Marine, collaborated with CKIPM to give a speech at this year's Jeju Forum for Peace and Prosperity, taking place on Jeju Island in Korea. ... read full story

Bellingham Marine designed and built New Superyacht Marina in the City of Aransas Pass, Texas

Written by

Comprising slips for boats up to 60’ with side-tie space for yachts up to 100’, the City of Aransas Pass in Texas saw the completion of the new superyacht marina, designed and built by Bellingham Marine. ... read full story

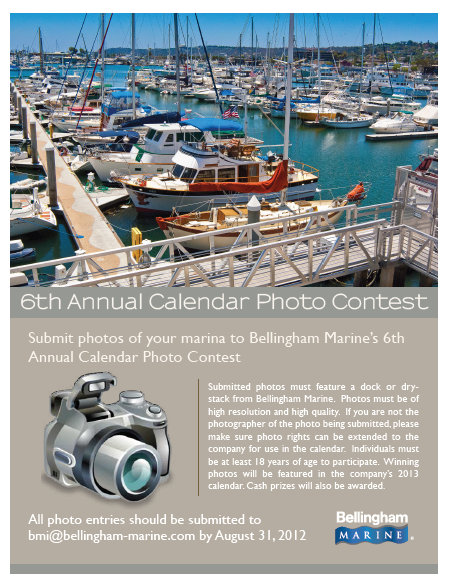

Bellingham Marine announces its sixth annual calendar photo contest

Written by

With photos due to be submitted online by August 31, one of the best marina design-build construction company, Bellingham Marine, has officially opened its 6th annual Calendar Photo Contest. ... read full story