The very first sailing yacht Swan 105 RS by Nautor’s Swan is currently under construction at the Finnish boatyard, Oy Nautor Ab. Luxury superyacht Swan 105 is a bold statement in luxury style and ocean-going performance, boasting innovative design as well as the use of ultra-modern materials.

Below is the genesis of the first luxury yacht Swan 105 RS, currently in build at the Finnish boatyard Oy Nautor Ab, as recounted by Project Manager Kristian Kjellman.

This is a special project for the Nautor team, as it combines the aspects of pure Swan as designed by naval architect German Frers, with an innovative interior and overall concept by Beiderbeck Design.

Frers Naval Architecture & Engineering followed all aspect of the hull design and performance. Inspired by his long standing relationship with the German firm, the owner asked Beiderbeck Design to turn his ideas into innovative interiors with a new layout concept.

This particular Swan 105 RS yacht began as a semi-custom performance cruiser with a spacious deckhouse and a generous sheltered cockpit with a permanent fixed bimini, and all the key elements of the “standard” Swan 105.

PROCESS MAKES PERFECT

Build of the superyacht Swan 105 RS began in early 2012 and the process was based on a sequence of specific steps which enabled Nautor to control the quality and follow their client’s requests. This is the first Swan 105 project that allowed the technical office to find the solution to each detail before producing the component or system.

It was clear from the outset that the project was going to be very demanding, likewise Nautor prepared the hull female tool with materials that would allow one curing process (including transom and bulwark, all inlays in the hull for windows, keel, P bracket and seacocks) to 90 degrees Celsius. This is definitely a work of art in its own right.

LEADING EDGE LAMINATION

The hull lamination process started in October 2012 and the hull was released from the tool after a very successful curing process on first week of January 2013. The Swan 105 RS yacht is being built with GL certificate for the hull and machinery and MCA, so Nautor’s work is followed in detail using approved drawings, materials and inspections during the building process. Nautor is the first yard to apply epoxy prepreg-SPRINT sandwich materials on such a large single component as the hull, a huge accomplishment for a structure of this size in one go with a “second to none” result.

A TOUCH OF COLOUR

After the hull was released from the mould, the team worked on the components inside the Swan 105 RS superyacht. The hull, ready for painting, was then moved to BTC (Boatbuilding Technology Centre) in Jakobstad in early February 2013.

Having used the female mould built using the CNC technology, the result was a very accurate surface on the released hull, therefore the preparation and fairing of the hull required less material between the hull structure and the finished paint surface.

HANDCRAFTED INTERIOR

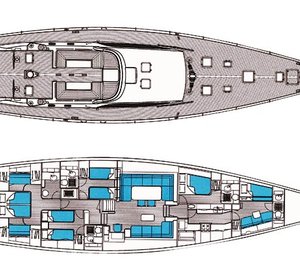

Meanwhile, at Nautor’s interior woodshop in Kronoby the team had already started with the interior components. This Swan 105 will have a special designed interior with many details customized to meet the client’s wishes in terms of style and comfort. The main components for the cabins where all pre-assembled and the details where completed to include wood trims for the headliners and also trims for the floorboards. The cabins were delivered to Nautor’s BTC (Boat Technology Centre) between August and December 2013.

INFRASTRUCTURE

Once the hull was prepared and the show coat applied, the team started working on the “infrastructure” process: the installations of the bilges – including tanks, hydraulics, electrical cabling, engine room preparations. This period started early summer 2013 and was completed at the end of September.

ALL SYSTEMS GO

After testing parts of the systems-installations, work on the interior began. The non-structural bulkheads were installed and from there the team moved on to the more critical parts, such as hanging lockers, beds, chart table and so on. Each area had been defined in detail in the early process and made to fit perfectly with the hull and installations. In December 2013, all the larger components were installed and the deck was ready to be mounted.

“This Swan 105 is intended to be very comfortable and we called an external consultant to work together with our own designers from the very beginning, with the aim of building a very quiet yacht with minimal noise disturbance. We used data from past projects and combined this with the most innovative materials and today’s expertise to reduce the noise level, especially in the owner’s and guest areas,” said Kristian Kjellmann, Porject Manager of the Swan 105.

The deck is built using the same methods as the hull, epoxy prepreg-sprint with sandwich. It consists of main deck, cockpit, crew cockpit and a fixed bimini with main sheeting point integrated in the bimini structure.

Nautor is now completing the installation of the saloon furniture, together with the deckhouse windows, the bimini and the cockpit furniture.

In the coming month dry testing will begin, before the first superyacht Swan 105 RS is launched and delivered in time for sailing this summer.

Below is a choice of the beautiful charter yachts built by Nautor’s Swan.